Heavy Oil Projects

Project Description

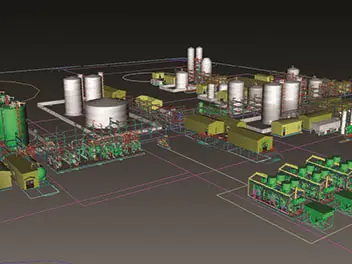

A competitor performed an initial pre-FEED study and proposed a high estimated cost to the client. Propak was then brought in to complete a FEED study to evaluate the design. This study concluded with Propak proposing a highly modularized plant solution taking advantage of Propak’s integrated EPF approach. Propak engineered, fabricated and constructed a modular plant creating schedule and cost advantages. Upon completion, the result was a $21M net reduction in actual project cost from the original estimate and an approximate 55% reduction in CPF footprint. A competitor performed an initial pre-FEED study and proposed a high estimated cost to the client. Propak provided cost and schedule certainty to the client though applying an integrated EPF solution along with a highly modularized, shop fabricated facility.

Project Specs

-

Services Provided