Heavy Oil Projects

Project Description

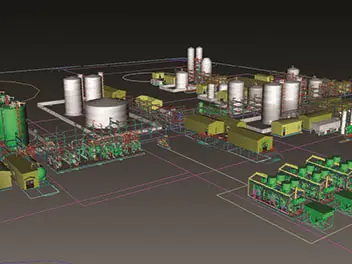

Propak provided engineering design, modular fabrication and on-site construction support for a series of well pad installations, central field facility upgrades and central processing facility debottlenecking projects. Well pad manifold building sections and vertical test separator building sections were developed to meet process and well spacing requirements. These building sections were designed to be fully modularized and repeatable. Subsequent well installations on multiple pads leveraged varying numbers and arrangements of these building sections. To further increase production, Propak completed debottlenecking projects within the CFF for the produced gas condensing system and within the CPF on the lift gas and steam distribution systems. A high pressure steam system was installed allowing for higher quality steam to be distributed to the new well pads.

Project Specs

-

Services Provided